woodworking homemade shopmade

square chisel machine

I needed the square holes, so I tried a Square Chisel attachment which can be set on the drill press. I hate my own work to make such square holes by hand chisel and hammer as made holes are far from perfect. Therefore, I once bought a square chisel bit to try on the small drill press. However it did not work. I needed strong press down force to make holes, but small drill press is not enough for this strong force.

When I make such square hores, I hammer the chisel into wood material. Small drill press canno to sustain this impact and force, therefore I thought the bigger drill press can sustain, I made an attachment for the bigger drill press.

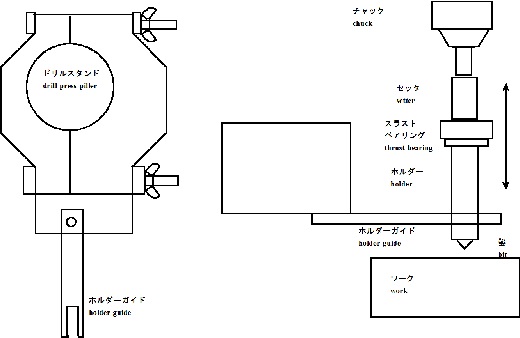

Above is the sketch to show how the attachment works. Square chisel outer holder is slide up and down in the guide and rotating bit make a hole on the work so that outer holder can cut the work in shape.

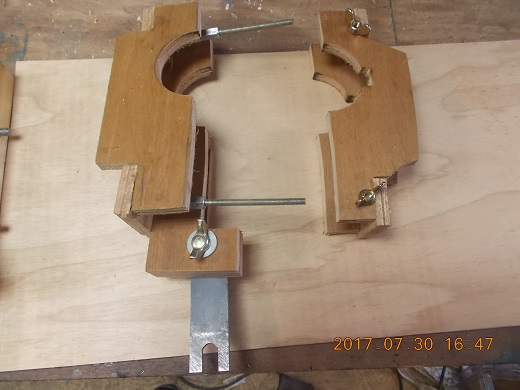

This is the completed attachment. This is set on the piller of the drill press.

Side view of the attachment. Lower guide is to receive the outer square holder of the chisel.

This is the square chisel bit. The rotating bit make hole and outer square holder cut the work. Therefore inner bit and outer holder must be pressed down in same speed. While making a hole, outer holder must not rotate but pressed down in the guide.

Bit accembly is set as shown above. The setter is fixed on the rotating bit and press down the square outer holder via a thrust bearing and washer by drill press rotating chuck.

The attachment is set on the drill press as shown above. Press down the chisel assembly by pressing down the lever. The guide of the attachment is fixed by the thum screw to adjust the guide position every time.

I could make the square holes by this attachment, but very strong force is needed, much more than estimated. To make hore at the precise position, I must make the fixing device.

However after several trials, I found that this attachment is not useable to make expected precise holes. Positioning is too difficult, and setting/removing takes too much time. If I make many holes, this attachment would be useful, but usually I make 2,3 holes. In my case, hand cutting is much easier and speedy.

Of cause, ready made machine can be used more easily to make fine holes, but this attachment cannnot satisfied holes.

Anyway, too strong force is neccessary to press down the chisel bit. I feel the drill press might cry "Stop abuse!!" This usage is not normal for the drill press.

I studied how the formal square chisel machine works. The outer square holder and inside bit are pressed down separately, unlike my attachment. This difference might cause some distortion resulting inaccurate position of the holes, and machine screams.

I tried to make a square hole by hand tools, and it was much better than work by attachment. And time was shorter even by my skill. My conclusion is :

This project is failed. I have no need to make a lot of square holes in my wood working, therefore hand work is more advantageous than machine work. And I do not want drill press abuse.

Article Index

return to home